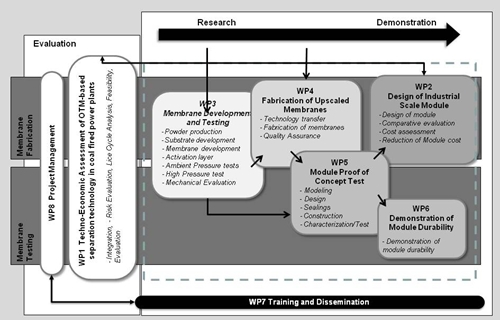

HETMOC is split into 8 WorkPackages (WP).

WP1 : Techno-Economic Assessment of OTM-Based Separation Technology in Coal Fired Power Pants

In WP1 conceptual designs of power plants integrating OTM technology will be evaluated with respect to energy efficiency and costs of integrated systems. HETMOC will investigate the integration of membrane separation technology in selected process schemes, as retrofit in existing IGCC power plants and in oxy-combustion plants using pulverised coal.

WP2: Design of Industrial Scale OTM Module

A 500 MW power plant would require of the order of 16,000 TPD oxygen (corresponding to a membrane area of 160,000 m2 with an average permeation rate of 5 ml min-1 cm-2). A membrane based oxygen production unit will on industrial scale consist of a number of smaller identical building units each holding several multiple tube bundles. Each unit encapsulated in a pressure vessel and connected to suitable piping systems for delivered oxygen and fed pressurized air. The magnitude of the air pressure depends on the way the membrane is integrated into the process. The primary objective of this task is to do a conceptual design of a single unit of an expected size of 100 TPD. A cost assessment of the module and sensitivity analysis will also be carried out which will be combined with strategic research to foster cost reduction of the next generation of OTM modules.

WP3: Membrane Development and Testing

WP3 will develop two types of oxygen transport membranes (OTMs) based on commercial type manufacturing processes. The WP will result in parent tubes that are selected for industrial up scaling. The WP will also include testing of oxygen transport and mechanical testing.

WP4: Fabrication of Upscaled Membranes

The main objectives of this WP is the upscale of the membrane manufacturing route developed in WP3 and to produce a series of membrane tubes for building the proof-of-concept module.

WP5: Module Proof of Concept Test

The main objectives of WP5 design, construct and test a multiple tube module that can hold 25 tubes of 1 m length. In order to guide the design phase, physical models of the different suggested designs will be developed and used in order to asses among others flow fields and the most critical mechanical problems expected to be encountered in HETMOC. In addition different sealing concepts will be developed and tested in WP5.

WP6: Demonstration of Module Durability

WP6 will undertake the medium sized durability demonstration of the optimized OTM process developed in HETMOC for a period exceeding 1000 hours. Besides demonstrating successful proof of concept of the scaled up OTM technology developed in HETMOC, the results of this testing work will be implemented in WP1 for final assessment/improvement of the integrated cycles. Key parameters identified during this testing period will be reported as fundamental insights for further improvement of the next generation of OTM modules.

WP7: Training and Dissemination

WP7 will focus on dissemination of the scientific results and new knowledge gained in research and development work packages to the scientific community and the general public via appropriate channels. In addition the WP will optimize research conditions and training to foster the development of a new generation of excellent scientists in this multidisciplinary and challenging research field with special attention to gender aspect. Also strong networking with other experienced researchers and experts in the field of OTM, and relevant industries will be established.

WP8: Management

The main task of this WP is high quality administrative management of the project both internally and externally to ensure that the S/T objectives are fulfilled.